In the age of automation and ever-evolving technology, industries across the globe are pushing boundaries to enhance efficiency, safety, and product quality. At the heart of this relentless pursuit of excellence lies one core principle: precision.

Precision: More Than Just Accuracy

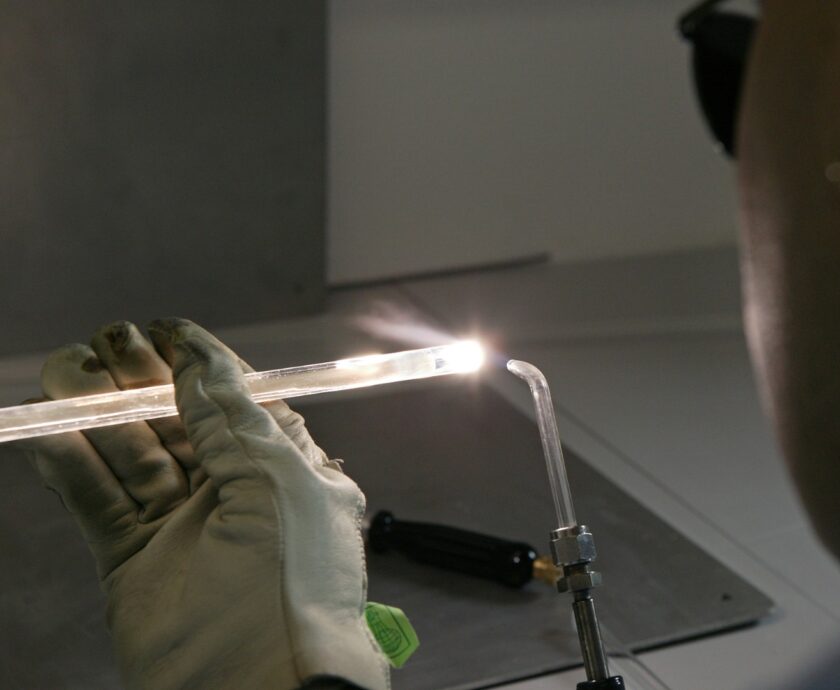

While accuracy ensures that something is correct, precision ensures it’s consistently and reliably so. In industrial contexts, this distinction can mean the difference between a thriving operation and a struggling one. For instance, consider aluminium smelting, a process heavily reliant on exact measurements from high-temperature sensors. Here, inconsistent readings, even if occasionally accurate, can lead to a cascade of challenges – from reduced product quality and increased operational costs to potential safety hazards. Precision, in such scenarios, becomes the bedrock upon which consistent quality and safety are built.

The Far-reaching Impacts of Precision

- Operational Efficiency: Precision allows for processes to run smoothly, with fewer disruptions. With machinery and processes finely tuned to operate under specific parameters, the entire system benefits. There are fewer breakdowns, less waste, and a more streamlined operation overall.

- Enhanced Product Quality: In many industries, the difference between a top-quality product and a subpar one is often a matter of minute variations. Precision ensures that these variations are minimised, leading to consistently high-quality outputs.

- Safety: Precise operations mean predictable operations. When processes run as they’re expected to, without unforeseen deviations, the risk of accidents or unforeseen complications decreases dramatically.

- Cost Savings: While investing in precision, be it through advanced equipment or expert consultations, might entail initial costs, the long-term savings are substantial. Reduced waste, fewer disruptions, less downtime, and decreased need for damage control all contribute to a healthier bottom line.

Precision in the Age of Customisation

In today’s industrial landscape, the one-size-fits-all approach is rapidly becoming obsolete. Different facilities, with their unique challenges and requirements, need solutions tailored to their specific needs. Enter custom solutions, like bespoke thermocouples designed for specific smelting environments. These solutions, rooted in a deep understanding of the unique challenges at hand, exemplify the role of precision in modern industries. They’re not just about getting things right; they’re about getting them right every single time.

Wrapping up

As industries continue to evolve, the role of precision becomes ever more central. It’s not just about doing things right; it’s about doing them right consistently, reliably, and efficiently. Whether it’s through the adoption of cutting-edge technologies, the integration of custom solutions, or a renewed focus on training and expertise, the path forward for industries across the board is clear. In the pursuit of excellence, precision isn’t just beneficial; it’s essential.