RTD Sensor & Helical Strake Thermowell Assembly for Oil & Gas Application

CATEGORY: Oil & Gas Temperature Assemblies

PRODUCTS:RTD, Helical Strake Thermowell Assemblies

DATE:June 2024

Background

Our customer, a leading engineering company in the oil & gas sector, required a reliable temperature sensing solution for their high-velocity offshore pipeline systems. These pipelines posed significant challenges due to the intense vibration and potential damage at high velocities, which standard thermowells could not withstand. The engineering team, led by a project engineer, sought an accurate and durable solution, while the procurement manager needed to ensure it met technical and budgetary constraints. The operations manager required seamless integration with existing systems.

SOLUTION

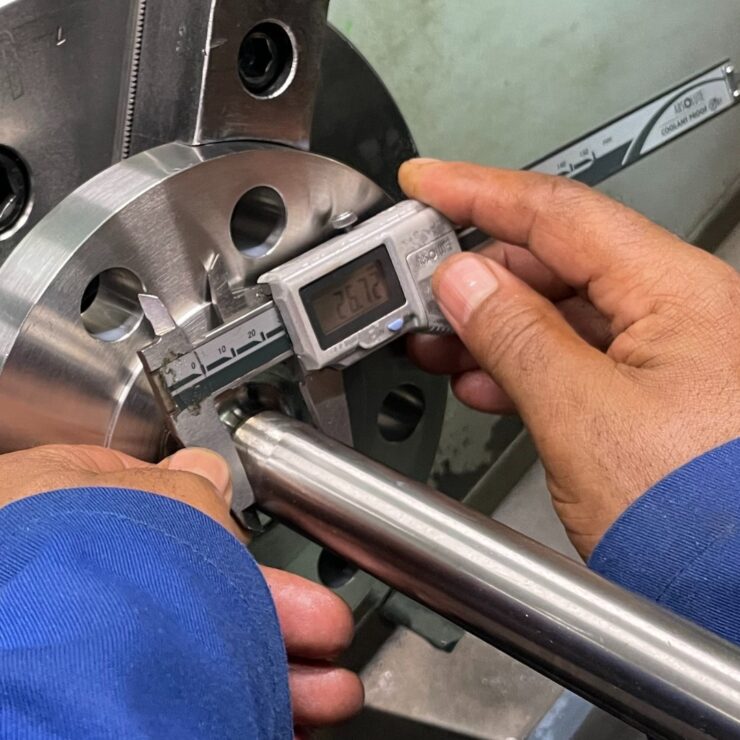

Thermo Electric Instrumentation provided a robust and tailored solution by recommending the use of helical strake thermowells combined with Resistance Temperature Detectors (RTDs). This design was specifically chosen to mitigate the issues associated with high-velocity environments, such as vibration and potential breakage, ensuring both the durability and accuracy of the temperature sensors. Our engineering team conducted a thorough analysis to optimize the placement and integration of these thermowells within the pipeline system. The helical design not only enhanced the structural integrity of the sensors but also allowed for more precise temperature measurements, critical for maintaining operational efficiency and safety in the offshore environment.

- Helical Thermowell Design: The helical shape effectively counteracts high-velocity vibrations, reducing the risk of damage and ensuring long-term reliability.

- Comprehensive Engineering Analysis: Extensive assessment and planning ensured optimal placement and integration of the thermowells and RTDs within the pipeline system.

- Rapid and Efficient Delivery: The project was completed ahead of schedule, with Thermo Electric delivering the customized solution in just 10 weeks, helping the customer maintain their project timeline and avoid costly delays.

Customised Services

Our approach was highly personalized from the initial consultation through to the final implementation. We worked closely with the customer's engineering team to understand their specific needs and challenges, ensuring that the helical thermowells and RTDs were precisely tailored to the unique conditions of their high-velocity offshore pipeline systems. Continuous engagement and updates throughout the project ensured that the solution was not only technically robust but also aligned perfectly with the operational objectives. Our commitment to delivering a customized solution was further demonstrated by our proactive customer support and the expedited delivery timeline, ensuring that the project stayed on schedule.

ENGINEERING EXCELLENCE

Our engineering excellence was pivotal in the success of this project. Utilizing state-of-the-art design software and extensive experience in temperature sensing technologies, our team conducted a comprehensive analysis to determine the optimal design and placement of the helical thermowells. This meticulous attention to detail ensured that the sensors would perform reliably under the harsh conditions of high-velocity pipelines. The technical superiority of the helical thermowell design effectively mitigated issues related to vibration and potential breakage, demonstrating our capability to deliver innovative and durable solutions in demanding environments.

RESULTS

Implementation of the Thermo Electric Instrumentation helical strake thermowell design, complete with RTDs, delivered significant benefits to the customer.

The advanced helical design substantially reduced the risk of vibration-induced damage, ensuring the long-term durability and reliability of the temperature sensors. This enhancement led to more accurate and consistent temperature measurements, which are critical for maintaining optimal operational efficiency and safety in the high-velocity offshore pipeline environment. The precise data allowed the operations team to make better-informed decisions, improving overall process control.

In addition, the expedited delivery and seamless integration of the system ensured that the customer’s project timeline remained on track, avoiding costly delays. The robust performance of the sensors will minimize maintenance requirements and downtime, translating into significant cost savings. Additionally, the tailored solution provided by Thermo Electric not only met but exceeded the customer’s expectations, reinforcing their trust and paving the way for future collaborations.

This project underscores our capability to deliver customized, high-quality temperature sensing solutions that address specific industrial challenges effectively.