MITIGATING FLASHBACK IN GAS TURBINES

CATEGORY: Hydrogen Gas Turbine Operations

PRODUCTS: Gas Turbine Temperature Sensors

DATE: January, 2023

Background

Hydrogen gas turbines are central to the clean energy transition, offering an alternative to fossil fuel-based power generation. However, operating these turbines comes with its unique set of challenges, most notably the risk of flashback. Flashback can not only result in severe equipment damage but can also pose significant safety hazards. One particular facility found itself regularly grappling with such issues, jeopardising both the efficiency and safety of its operations. The risk of flashback had led to multiple operational disruptions, causing substantial financial and reputational damage. Given the severity and frequency of these events, it was therefore, extremely important to find a robust, long-term solution to mitigate the associated risks.

SOLUTION

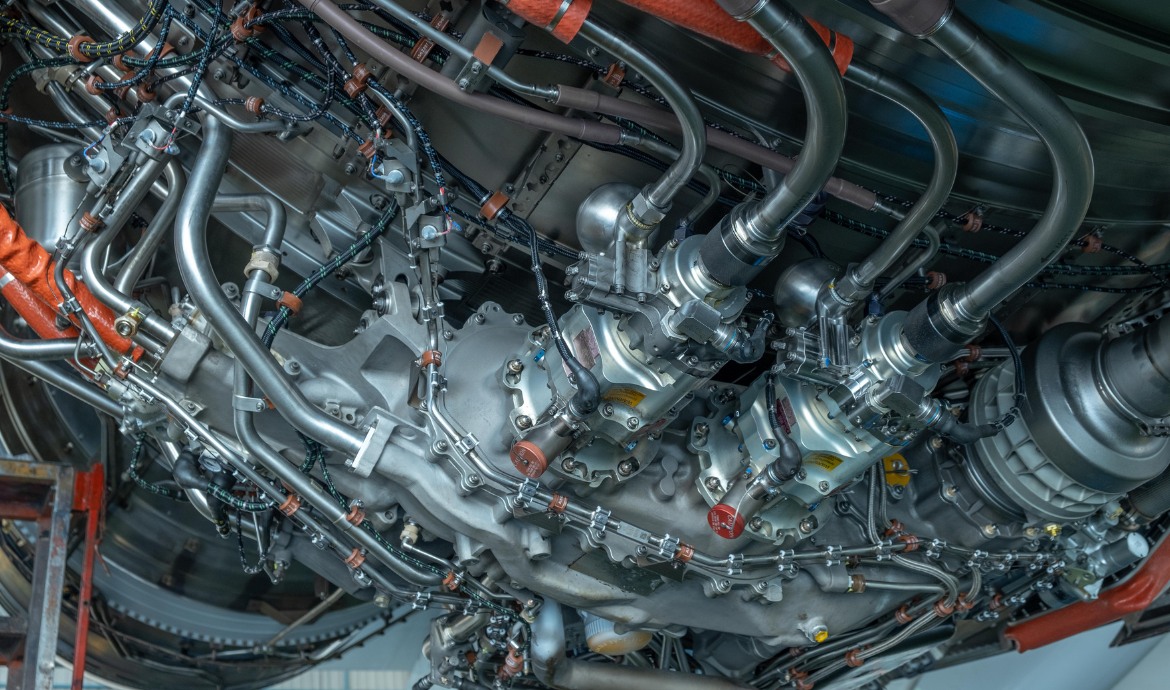

To tackle the inherent risks of flashback, a special set of engineered solutions was developed. These solutions incorporated cutting-edge sensor technology and specialised burner designs that significantly reduced the incidence of flashback. The new sensors were retrofitted into the existing system, minimising downtime and avoiding any need for major infrastructural changes. These features were integrated seamlessly, ensuring a holistic approach to mitigating the flashback risks that had plagued the plant.

Customised Services

Understanding the unique complexities of gas turbines, a highly personalised approach was adopted right from the start. The project requirements and constraints were mapped out in detail, ensuring that the proposed solutions would fit seamlessly into existing processes. Close communication with the client was maintained throughout the project, from initial scoping to final implementation

ENGINEERING EXCELLENCE

A cornerstone of the project's success was a staunch commitment to engineering excellence. Each component was subjected to stringent quality control measures to ensure it met all industrial safety and performance standards. This meticulous attention to engineering details was pivotal in designing a system that was both effective in mitigating risks and robust in its construction.

RESULTS

The gas turbine temperature sensing solution that we provided had an array of positive impacts on the performance of the turbine:

- Reduced Incidence: There was a marked reduction in the incidence of flashback, significantly improving the safety profile of the turbine.

- Operational Efficiency: With fewer disruptions, the turbines operated more efficiently, resulting in increased power generation and reduced operational costs.

- Enhanced Safety: By mitigating the risks of flashback, the plant saw improved compliance with safety regulations.

- Cost Savings: Fewer incidents meant reduced repair and downtime costs, providing significant long-term savings.

- Reputational Gains: The successful resolution of a major operational challenge enhanced the plant’s standing as a reliable and safe operator in the clean energy sector.

In summary, the proactive approach to engineering and tailored services led to a highly effective solution for mitigating flashback risks, enhancing the safety, efficiency, and reputation of the hydrogen gas turbine facility.