High-Performance Temperature Measurement Solution for Large-Scale Energy Project

CATEGORY: Energy

PRODUCTS:RTDs, Thermowells, Multipoint Assemblies

DATE:March 2020

Background

A major energy project required advanced temperature sensing solutions to ensure precise monitoring and operational safety in a highly complex industrial environment. The customer, a leading entity in the energy sector, needed a reliable supplier capable of delivering customized temperature sensors, including RTDs, thermocouples, skin-type thermocouples, and multipoint thermocouples. With multiple suppliers competing, Thermo Electric was selected due to its deep technical expertise, proven product quality, and ability to meet strict compliance standards. The project required engineering solutions that could withstand high temperatures, high pressure, and corrosive conditions, ensuring long-term performance and accuracy.

SOLUTION

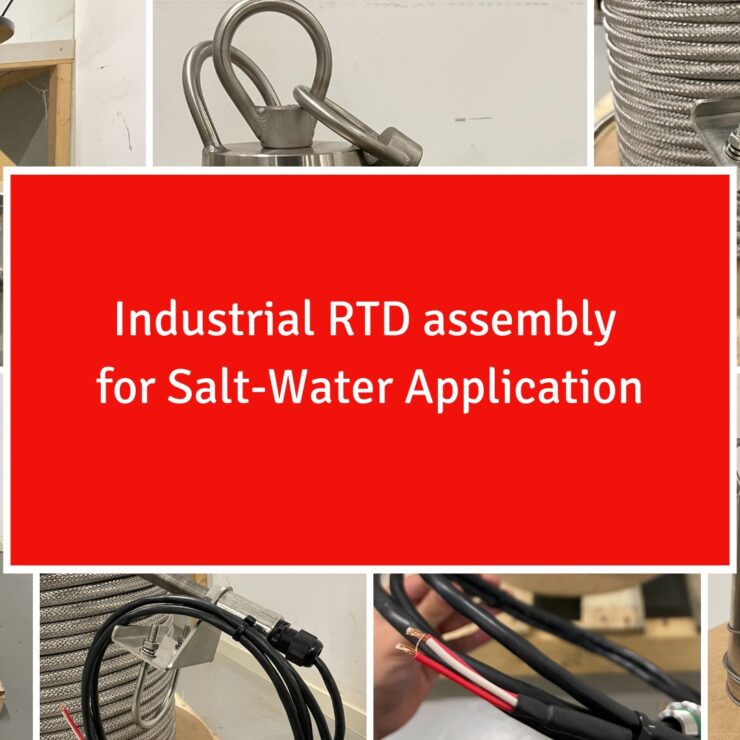

Thermo Electric provided a tailored solution by engineering temperature sensors specifically designed for extreme conditions. Each sensor type was customized to ensure accurate measurement, durability, and compliance with industry standards. The supplied components included multipoint thermocouples for precise temperature profiling, RTDs with thermowells for stable process control, Type B and Type K thermocouples for high-temperature environments, and skin-type thermocouples for monitoring surface temperatures of pipelines and vessels. These custom solutions were critical in maintaining process efficiency and operational reliability in a demanding industrial setting.

Technical Modifications

Our engineering team made several key modifications to standard designs to enhance the sensors' resilience under extreme conditions. Thermowells were manufactured using high-performance materials such as stainless steel, Inconel, and Hastelloy, ensuring durability against high temperatures and corrosive environments. Advanced mounting techniques and reinforced structures were implemented to withstand high-velocity process flows and mechanical stress. Wake frequency calculations were conducted to ensure compliance with stringent industry safety standards, optimizing sensor performance and longevity.

Customized Services

Understanding the complexity of the project, Thermo Electric provided a highly personalized service to meet the customer's specific requirements. From initial design consultation to final delivery, our team worked closely with the customer to ensure seamless integration of our solutions. Custom engineering support, rapid prototyping, and strict adherence to compliance regulations were key aspects of our service. This proactive approach enabled us to deliver a solution that met all technical specifications while ensuring timely execution within the project’s tight schedule.

RESULTS

The successful manufacturing and delivery of these customized temperature sensors provided significant operational benefits to the customer. The enhanced thermowell and sensor designs ensured durability, accuracy, and long-term reliability in high-temperature and high-pressure environments. These improvements contributed to increased operational efficiency, reduced maintenance requirements, and enhanced process safety.

Despite the complexity and scale of the order, we delivered all items on time, aligning with the customer’s project schedule and preventing costly delays. The project was completed within the planned timeframe, demonstrating our ability to execute large-scale contracts efficiently. Our ability to deliver high-quality, tailored solutions strengthened the customer’s confidence in our capabilities, setting the stage for future projects. The work we did here further established Thermo Electric as a leader in providing advanced temperature measurement solutions for critical energy infrastructure.