Engineering Excellence in High-Pressure Thermocouples

CATEGORY: High Pressure Thermocouples

PRODUCTS:Customised High-Pressure Temperature Sensors

DATE:Oct 2023

Background

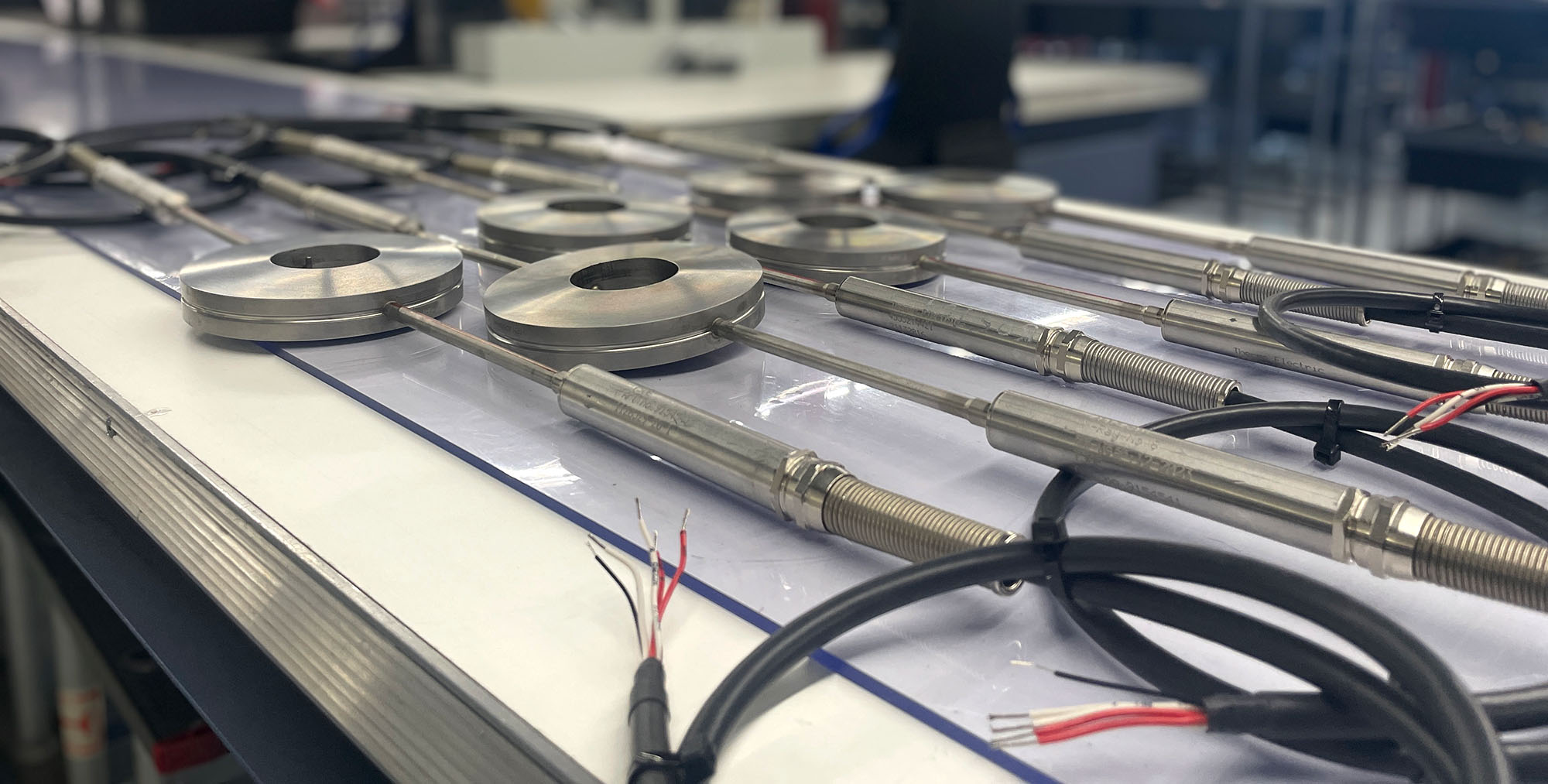

Recently, we partnered with a German leader in producing high-pressure components for LDPE plants. With operational pressures reaching 2000 bar, they required temperature sensors that are precise and resilient under extreme conditions. Thermo Electric’s mission was to understand their specific challenges to design a bespoke solution, focusing on the reliability and efficiency of critical high-pressure components like pipes, reactors, valves, and pumps.

SOLUTION

Our solution encompassed exhaustive testing and custom design. We recommended pressure testing up to 4600 bar at ambient temperature to validate the sensors’ resilience. Our process included:

- Design: Manufacturing sensors to handle up to 2000 bar.

- Testing: Rigorous evaluations, testing sensors up to 4600 bar at room temperature.

- Certification: Providing detailed test reports and certifications.

- Production: Proceeding to full-scale manufacturing tailored to their specifications.

This approach ensured seamless integration of robust sensors into their high-pressure systems, enhancing safety, accuracy, and efficiency in their LDPE projects.

Customised Services

Our partnership was built on trust and continuous collaboration. By maintaining open communication and understanding our customer's needs, we provided tailored solutions that underscore our expertise in the high-pressure sector and drive advancements in LDPE component technology.

ENGINEERING EXCELLENCE

Our team's expertise in high-pressure environments was pivotal. The project showcased our ability to design and manufacture temperature sensors that can withstand extraordinary pressures, reinforcing our reputation for engineering excellence and innovation in challenging industrial applications.

RESULTS

The culmination of this project with our German partner in high-pressure component manufacturing for LDPE plants marks a significant milestone for Thermo Electric Instrumentation. Our custom-designed temperature sensors, capable of enduring pressures up to 4600 bar, have set a new standard in the industry for durability and precision. This advancement has not only enhanced the operational safety and efficiency of LDPE plants but has also solidified our reputation as innovators in high-pressure technology.

The successful integration of these sensors into the client’s systems has led to a marked improvement in their operational accuracy and reliability. This project exemplifies our commitment to pushing the boundaries of what is possible in temperature measurement and control in extreme environments. It stands as a testament to our engineering prowess and our dedication to meeting the unique challenges of our clients with tailor-made, cutting-edge solutions.

Overall, this project has strengthened our long-standing relationship with the client, reinforcing our role as a key player in advancing the technological frontiers of the LDPE industry. It highlights our ability to not only meet but exceed the expectations of our clients, ensuring their continued trust and collaboration in future high-stakes projects.