BOOSTING EFFICIENCY AND UPTIME IN AMMONIA PRODUCTION

CATEGORY: Ammonia Production

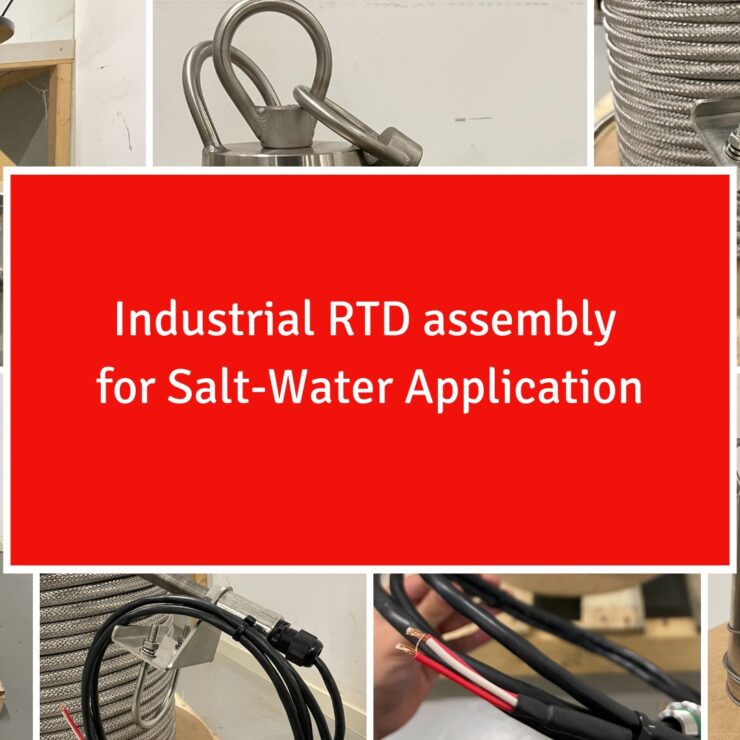

PRODUCTS: Advanced Industrial Temperature Sensing

DATE: January, 2022

Background

The ammonia production industry, a critical component of the agricultural and manufacturing sectors, is governed by stringent efficiency metrics and uptime requirements. A cornerstone of this efficiency is the accurate and reliable measurement of temperature variables during the production process. However, one specific facility faced significant challenges related to sensor inaccuracies, frequent maintenance, and unplanned outages. These issues were causing a domino effect of reduced efficiency, higher costs, and increased downtime, thus necessitating an urgent intervention.

SOLUTION

To tackle these challenges head-on, Thermo Electric’s industrial temperature sensors were introduced into the ammonia production facility. Known for our robustness and reliability, these advanced sensors were designed to operate under the harsh conditions typically present in ammonia production. Their seamless integration into the existing control systems, along with their high-degree accuracy, contributed to a marked improvement in process control. As a result, the plant observed a decline in both maintenance events and unplanned outages.

Customised Services

The solutions provided were meticulously tailored to the plant's unique operational challenges. Regular consultations with on-site personnel were held to ensure that the new corrosion-resistant sensors aligned closely with operational needs and could be easily integrated into the existing infrastructure.

ENGINEERING EXCELLENCE

The success of this project rested heavily on Thermo Electric's engineering capabilities. Utilising advanced materials, we developed temperature sensors that offered unparalleled durability and accuracy. Each assembly underwent stringent quality checks, ensuring it met or exceeded the industry standards.

RESULTS

The deployment of Thermo Electric’s industrial temperature sensors led to an array of positive outcomes:

- Extended Sensor Lifespan: The new sensors required far fewer maintenance interventions.

- Increased Operational Efficiency: Accurate temperature data resulted in improved process control, thereby enhancing output quality and yield.

- Reduced Costs: The lowered frequency of sensor replacement and maintenance led to significant cost savings.

- Enhanced Uptime: The reliable sensors contributed to a substantial reduction in unplanned outages.

The introduction of our Thermo Electric industrial temperature sensors provided a robust solution to the complex challenges faced by the ammonia production facility. The improvements in efficiency, uptime, and cost-effectiveness have set a new benchmark for the industry.