ALUMINIUM SMELTING THERMOCOUPLES

CATEGORY: Aluminium Smelting

PRODUCTS: Custom Thermocouple Solutions

DATE: June, 2022

Background

Aluminium smelting is a process that demands meticulous control over temperature variables to ensure product quality and operational efficiency. Inconsistent temperature measurements can lead to a host of challenges, including decreased product quality, increased operational costs, and heightened safety risks. A specific smelting facility was grappling with these issues, primarily caused by thermocouples that were failing to provide accurate and consistent temperature readings. This had led to frequent process disruptions, reduced throughput, and higher operating costs, making the need for an innovative solution increasingly urgent.

SOLUTION

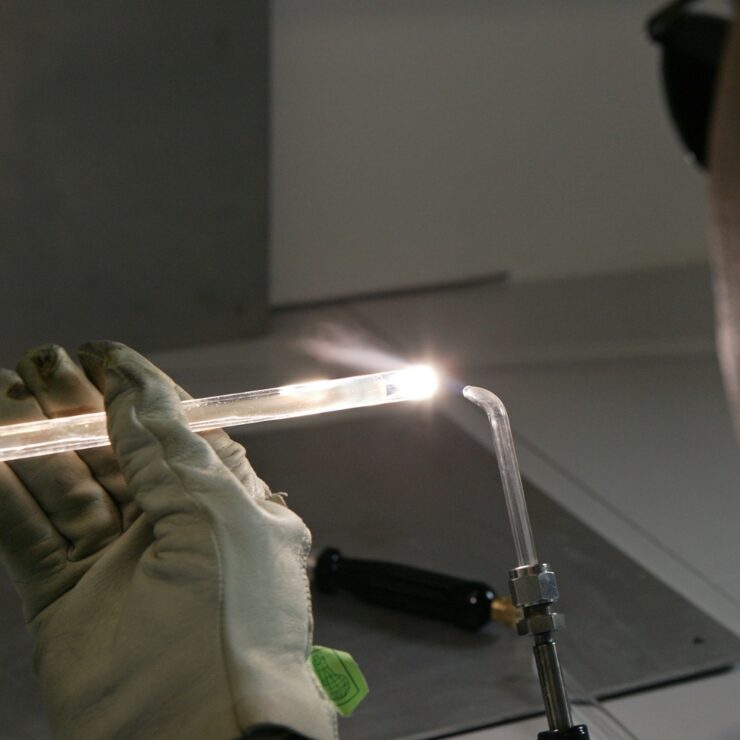

In light of these challenges, Thermo Electric was approached to provide a tailored solution. Harnessing our extensive expertise in the field, we designed custom thermocouples that not only provided superior accuracy but also offered increased longevity. These thermocouples were manufactured using special materials able to withstand the harsh conditions within the aluminium smelting furnaces. Their compatibility with existing systems also facilitated a smooth transition, minimising any interruptions to the plant’s operations.

Customised Services

Our bespoke approach involved a pre-installation consultation to identify the unique operational challenges the facility was facing. This ensured that the custom thermocouples were designed to meet the exact needs of the plant. Continuous communication throughout the implementation process allowed for timely adjustments, ensuring that the project was completed on schedule and met all its objectives.

ENGINEERING EXCELLENCE

The core strength of what we do lies in our unwavering commitment to engineering excellence. Our experience in this sector enabled us to provide a solution for custom thermocouples that exceeded the customer requirements. The selection of durable and resistant materials ensured longevity, offering the customer and the site a dependable, long-term solution.

RESULTS

The impact of implementing high-temperature thermocouples designed and manufactured by Thermo Electric Instrumentation was multifaceted:

- Enhanced Accuracy: The new thermocouples provided significantly more accurate temperature readings.

- Operational Efficiency: More accurate data led to optimised process control, improving the overall efficiency and output quality.

- Cost Reduction: Enhanced durability of the thermocouples meant lower replacement and maintenance costs.

- Safety Improvements: Reliable data helped maintain a more stable and secure operating environment.

In summary, the introduction of our custom thermocouples effectively addressed the complex and critical challenges facing the aluminium smelting facility, paving the way for improved accuracy, efficiency, and cost-effectiveness.