In the pursuit of clean energy alternatives, hydrogen gas turbines stand out as one of the most promising avenues. As an answer to the global call to reduce dependence on fossil fuels and combat climate change, these turbines represent a cleaner, more sustainable future for power generation. Yet, with the promise of a greener tomorrow comes a set of unique challenges, most notably the risk of flashback.

Flashback is a phenomenon in combustion where the flame travels upstream of its intended location. This poses a risk not only to the system but also to the overall safety of operations. Recurring issues of flashback can have detrimental effects, including decreased operational efficiency, potential equipment damage, and even significant safety hazards.

Given the critical role hydrogen gas turbines play in the clean energy transition, mitigating these risks has become an engineering challenge.

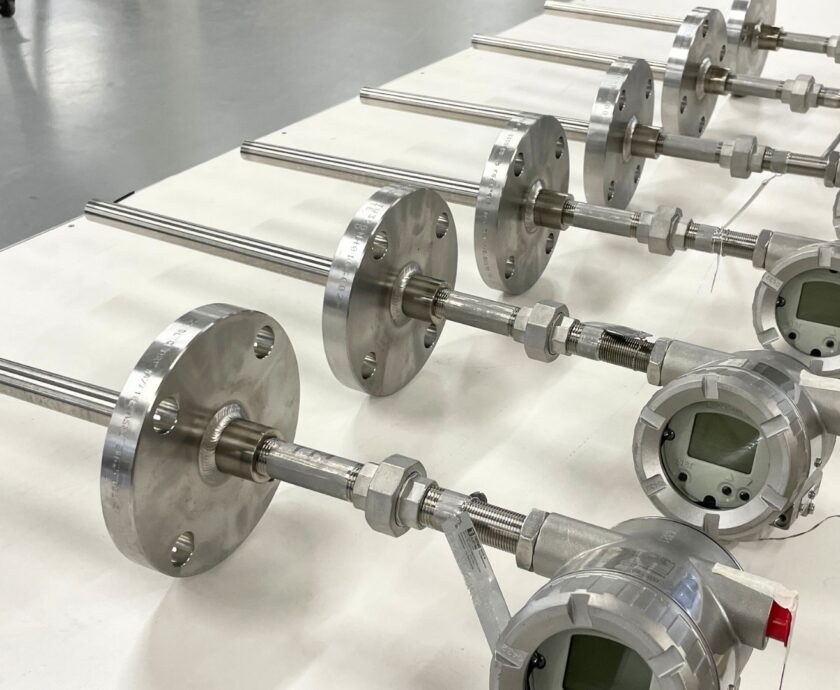

Incorporating Advanced Sensor Technology: To ensure early detection and real-time monitoring of combustion environments, bespoke engineered gas turbine temperature sensors can be introduced. These temperature sensors, designed with precision, can detect minute changes in combustion parameters, thus allowing for prompt interventions when any anomaly is detected. The adaptability of these sensors is a key feature in order for them to be seamlessly integrated into existing turbine systems, eliminating the need for extensive modifications or prolonged downtimes.

Revolutionising Burner Design: Beyond detection, there are also reported advantages in reevaluating the very heart of the combustion process. For example, changes to the burner design can further optimise gas flow and combustion parameters with the overall aim of creating a burner that inherently reduces the conditions leading to flashback. The end result is a revised design that helps to minimise the occurrence of flashback, ensuring a consistent, stable, and safe combustion process.

This two-pronged approach — precision, real-time monitoring coupled with an innovative combustion design — has been reported to offer a robust solution to the flashback challenge. With the integration of precision temperature sensors and a new burner design, some systems have witnessed a decline in flashback incidents. What was once a recurring disruption can potentially become an infrequent occurrence, leading to heightened operational efficiency and a notable increase in safety standards.

The journey towards cleaner energy solutions is fraught with challenges, but they are not insurmountable. Flashback in hydrogen gas turbines, while a significant issue, can be effectively managed with the right blend of technology and innovative design. Such measures not only ensure the safe and efficient operation of turbines but also increase confidence in the clean energy transition. As the global community continues its march towards a more sustainable future, it’s imperative to address challenges head-on, reinforcing the commitment to a cleaner, greener tomorrow.