In our world of industrial temperature measurement, particularly within thermocouple manufacturing, every detail matters. Each component comes under scrutiny when seeking the ultimate in reliability and performance, in order to guarantee accurate readings. A key part of this mix is the Mineral Insulated cable commonly referred to as MI cable. In this article we’ll explore the ins and outs of MI cable; including its composition and ultimately how we use it when making our thermocouples.

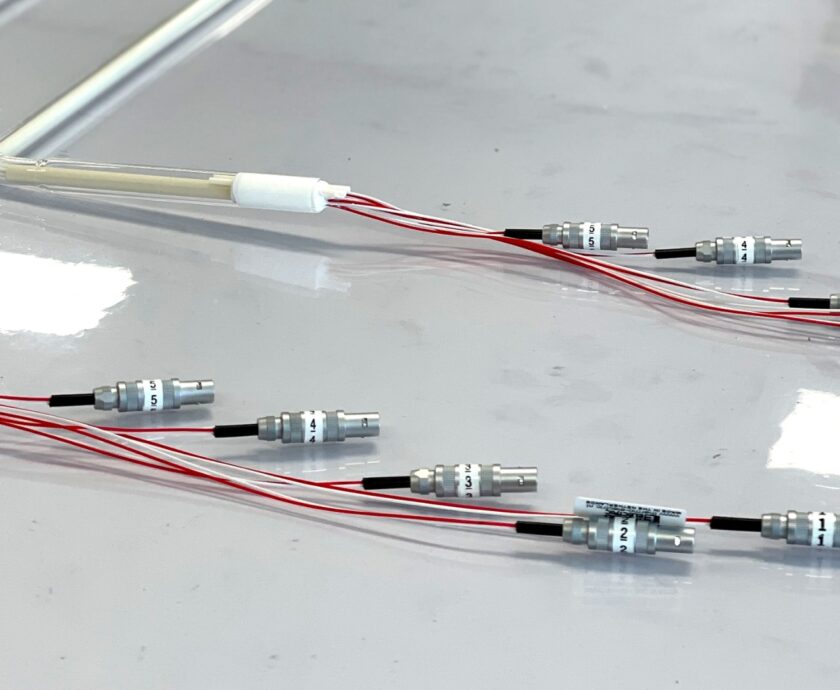

MI cable is distinct in its construction. It’s made up of thermocouple wires, encased within a metal sheath. The sheath acts as a protective boundary, which is filled with densely compacted magnesium oxide powder, this acts as the insulator. The main purpose of this construction is to provide a protective environment for the thermocouple wires, defending them against external contaminants and potential corrosion.

Now let’s take a step back and talk about the mighty Thermocouple and how that works. If you’ve heard of Thomas Seebeck then you may also know about the Seebeck effect: a phenomenon where temperature differences between two different metal junctions generate a voltage. Maintaining the integrity and consistency of this voltage, and by extension, the temperature reading, is paramount. This is where MI cables come into play. It ensures that the sensitive wires inside a thermocouple remain untouched by external factors, thereby maintaining the accuracy of the measurements.

Advantages of Using MI Cable:

- Durability: Given their robust construction, MI cables exhibit a high resistance to adverse environmental conditions, including high temperatures and corrosive atmospheres.

- Flexibility: Despite their durable nature, MI cables are surprisingly flexible, allowing for installation in intricate configurations and challenging locations.

- Enhanced Thermal Response: The compact magnesium oxide insulation ensures that the conductors inside are in close contact with the sheath, promoting rapid thermal response. This means thermocouples can detect and respond to temperature changes swiftly.

- Electrical Isolation: The dense insulation offers excellent electrical isolation, minimising the risk of short circuits or electrical interference, which can compromise measurement accuracy.

- Safety: Given their construction, MI cables are inherently fire-resistant, reducing potential fire hazards in high-temperature applications.

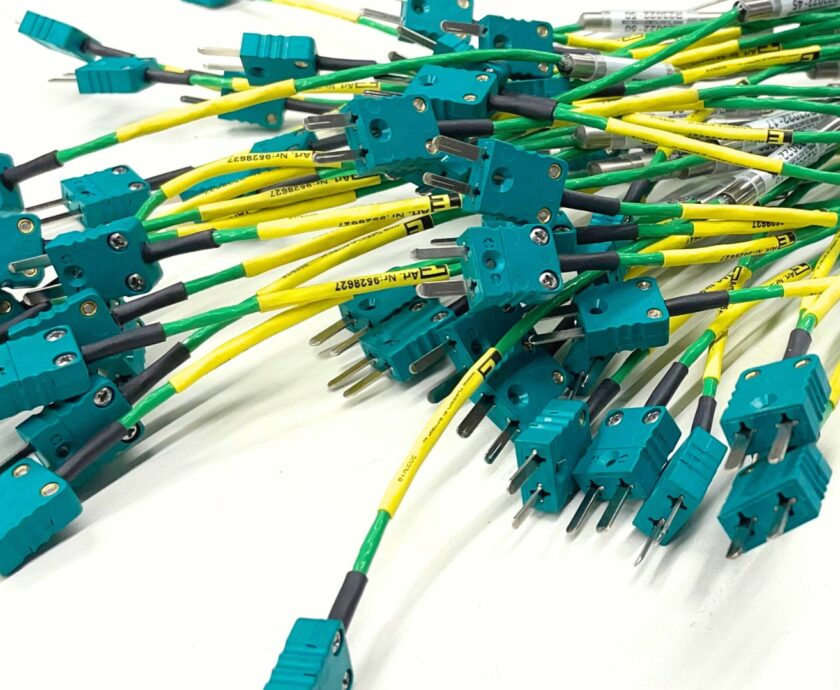

The integration of thermocouples in Mineral Insulated cables is no coincidence. Their unique properties make them a valuable asset in the pursuit of precise temperature measurement.

As industries continue to evolve and demand more from their equipment, the role of MI cables in ensuring reliability and precision becomes ever more evident.