In many industries, measuring temperature in confined or difficult-to-access areas can be a challenging task. Whether it’s inside an aircraft engine, a semiconductor device, or medical equipment, tight spaces demand specialized sensors that are compact yet capable of delivering precise measurements. This article explores the advantages of using miniature sensors for temperature measurement in such spaces, helping you choose the right solution for your needs.

The Challenges of Measuring Temperature in Confined Spaces

Measuring temperature accurately in tight or restricted areas presents several challenges:

- Limited Space for Installation: Many applications do not have sufficient room to accommodate traditional temperature sensors. This can be a significant limitation when space efficiency is critical.

- Maintaining Accuracy: In confined spaces, sensors may be exposed to thermal interference from nearby components. Ensuring that temperature readings are accurate and not influenced by other elements is crucial.

- Access for Maintenance: The difficulty of accessing sensors for calibration or replacement is another concern, particularly in applications where disassembly is complex or time-consuming.

Miniature Sensors: An Ideal Solution

Miniature sensors are specifically designed to address the challenges of confined spaces. They are small, lightweight, and can be customized to meet the unique requirements of various applications. Here are some of the main advantages of using miniature sensors:

- Compact Design: Miniature sensors have a reduced size, allowing them to fit into tight spaces where conventional sensors would not be feasible. This is particularly important in applications like aerospace, automotive, and semiconductor manufacturing.

- High Accuracy: Despite their small size, miniature sensors provide high-accuracy measurements. They are designed to be highly responsive and can accurately detect temperature changes in real time, making them suitable for applications that require precise control.

- Customization Options: Miniature sensors can be customized in terms of sheath materials, length, and termination options, allowing them to be tailored to specific environments and operational requirements.

Types of Miniature Sensors

There are several types of miniature sensors that can be used for measuring temperature in confined spaces, each with unique features suited to different applications:

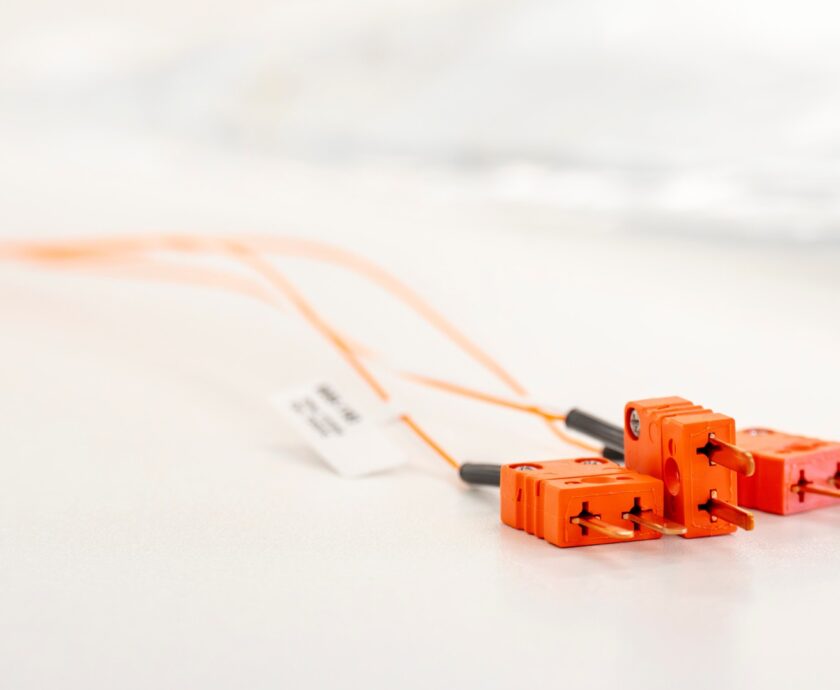

- Miniature MI-Cable Thermocouples

Mineral-insulated (MI) cable thermocouples are versatile and well-suited for high-temperature applications. They offer flexibility and durability, with a small diameter that makes them ideal for restricted spaces. MI-cable thermocouples are commonly used in:

- Aerospace: Monitoring engine components and hydraulic systems.

- Semiconductor Manufacturing: Measuring wafer temperatures during processing.

- Medical Devices: Incorporating temperature sensors into catheters and other diagnostic equipment.

- Spring-Loaded Thermocouples

Spring-loaded thermocouples are designed for applications that require good contact between the sensor and the surface being measured. These sensors are suitable for environments where rapid temperature changes occur, as they provide consistent pressure and optimal thermal conductivity. Applications include:

- Plastic Processing: Measuring mold temperatures during injection molding.

- Automotive Components: Monitoring temperatures in engine parts that experience rapid fluctuations.

- Subminiature RTDs

Resistance temperature detectors (RTDs) provide high accuracy and stability, making them ideal for applications requiring precise temperature monitoring. Subminiature RTDs are particularly useful in:

- Industrial Automation: Monitoring temperatures in small actuators or control systems.

- Food Processing: Ensuring accurate temperature readings in confined equipment spaces.

Selecting the Right Miniature Sensor

Choosing the right miniature sensor for your application involves considering several key factors:

- Temperature Range: Consider the temperature range your application requires. Thermocouples are suitable for higher temperatures, while RTDs offer higher accuracy at moderate temperatures.

- Response Time: In applications where temperature changes rapidly, selecting a sensor with a fast response time is crucial to maintaining accurate control.

- Sheath Material: The environment in which the sensor will be used determines the best sheath material. For example, Inconel is suitable for high-temperature environments, while stainless steel may be preferred for its corrosion resistance.

- Termination Options: Miniature sensors can be customized with various terminations, such as miniature plugs, flexible lead wires, or threaded fittings, to facilitate easier installation and integration into the system.

Applications of Miniature Sensors

Miniature sensors are employed in a wide range of industries where space constraints and precise temperature measurement are crucial:

- Aerospace Systems: In aerospace, miniature sensors are used in engine compartments, hydraulic lines, and avionics to monitor temperature without adding significant weight or bulk.

- Semiconductor Manufacturing: During the production of semiconductor wafers, precise temperature control is necessary to maintain product quality. Miniature sensors help monitor temperature within tight equipment spaces.

- Medical Devices: Miniature sensors are used in medical diagnostics and treatment devices, such as catheters and endoscopes, where accurate temperature measurement is essential without compromising patient comfort.

Benefits of Using Miniature Sensors

- Space Efficiency: The compact size of miniature sensors makes them perfect for applications with limited space.

- High Precision: Miniature sensors provide accurate and consistent measurements, ensuring that processes remain within their desired parameters.

- Versatility: With customization options for sheath material, length, and terminations, miniature sensors can be adapted to fit a wide range of applications and environments.

Conclusion

Measuring temperature in tight spaces requires specialized solutions, and miniature sensors are designed specifically to meet these challenges. With their compact design, high accuracy, and customization options, they provide reliable temperature monitoring in even the most confined environments. By choosing the right miniature sensor for the specific application, industries can ensure precise temperature control, improve product quality, and enhance overall process efficiency.

Whether used in aerospace, semiconductor manufacturing, or medical devices, our miniature temperature sensors offer a versatile and effective solution for challenging temperature measurement needs in confined spaces.