ISO certifications play an important role in ensuring the highest standards of quality and safety in temperature sensor manufacturing. These globally recognized standards guarantee that products and services meet consistent criteria for excellence. This article explores the importance of ISO certifications in temperature sensor manufacturing, highlighting how our comprehensive range of certifications benefits end users and protects the valuable human assets within manufacturing organizations.

What Are ISO Certifications?

ISO (International Organization for Standardization) certifications are globally recognized standards that ensure products and services meet consistent quality and safety criteria. These standards are developed through a consensus process involving international experts and cover a wide range of industries and processes.

Key ISO Certifications for a Reputable Manufacturer

To be recognized as a reputable manufacturer, adherence to several ISO certifications is essential. These certifications demonstrate a commitment to maintaining high standards in various aspects of manufacturing:

- ISO 9001: Quality Management Systems

- Purpose: Ensures consistent quality in products and services.

- Benefits: Enhances customer satisfaction, operational efficiency, and continuous improvement.

- ISO 14001: Environmental Management Systems

- Purpose: Provides a framework for environmental management practices.

- Benefits: Reduces environmental impact, ensures regulatory compliance, and promotes sustainable practices.

- ISO 45001: Occupational Health and Safety Management Systems

- Purpose: Ensures safe and healthy workplaces.

- Benefits: Reduces workplace risks, enhances employee safety, and improves overall health and safety performance.

- ISO/IEC 17025: General Requirements for the Competence of Testing and Calibration Laboratories

- Purpose: Ensures that laboratories operate competently and generate valid results.

- Benefits: Guarantees accurate and reliable calibration services, which are critical for precise temperature measurement.

The Role of ISO Certifications in Temperature Sensor Manufacturing

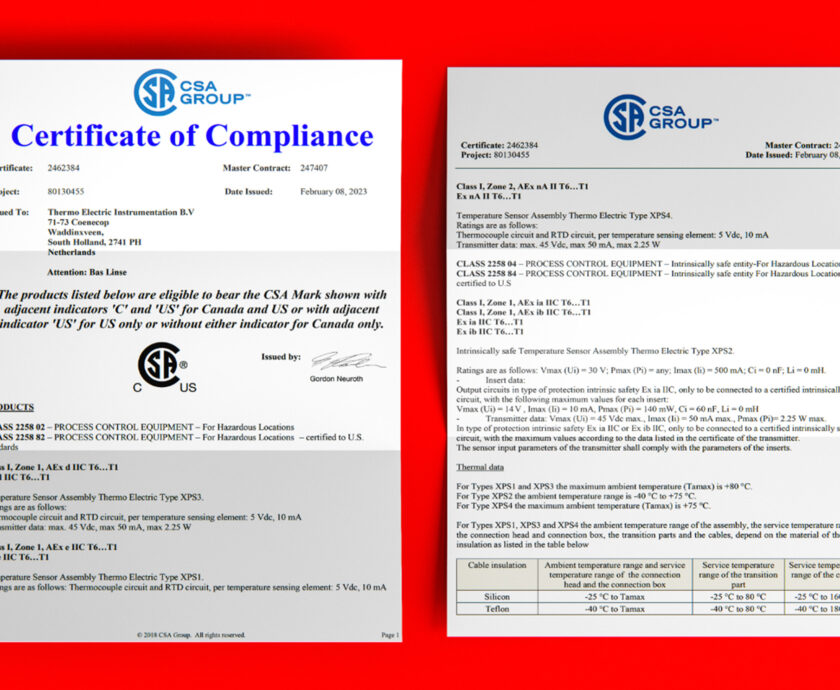

ISO certifications provide a structured framework for maintaining high standards in various aspects of manufacturing. At Thermo Electric Instrumentation, we hold all these key certifications, reflecting our commitment to excellence and our status as a reputable industry leader.

- Quality Assurance: Our ISO 9001 certification ensures that temperature sensors are manufactured through processes that prioritize quality at every stage. This includes rigorous testing, inspection, and documentation practices that guarantee product reliability and performance.

- Environmental Responsibility: Our ISO 14001 certification demonstrates a commitment to minimizing environmental impact. We implement sustainable practices, reduce waste, and ensure compliance with environmental regulations.

- Health and Safety: Our ISO 45001 certification highlights our dedication to maintaining a safe working environment. Protecting our workforce is a top priority, and this certification involves identifying potential hazards, implementing preventive measures, and continuously monitoring and improving safety protocols. By adhering to ISO 45001 standards, we ensure that our employees, who are our most valuable assets, operate in a safe and healthy environment.

- Calibration Accuracy: Our ISO/IEC 17025 certification is critical for our laboratory, which performs testing and calibration of temperature sensors. This certification ensures that our calibration processes are accurate, reliable, and meet international standards, providing confidence in our sensors’ performance across various applications.

Benefits for End Users

ISO certifications offer several benefits to end users of temperature sensors:

- Enhanced Reliability: Companies that adhere to professional standards are more likely to operate in a way that puts the customer at the heart of key decisions. This approach results in products that are consistent and therefore reliable. Sensors manufactured under ISO-certified processes are more reliable, ensuring consistent and accurate temperature readings critical for industrial operations.

- Quality Assurance: ISO 9001 certification guarantees that the sensors meet high-quality standards, providing peace of mind to end users regarding the performance and longevity of the products.

- Accurate Calibration: ISO/IEC 17025 ensures that the sensors are precisely calibrated, offering reliable data essential for process control and optimization in various industries.

Wrapping up.

ISO certification is vital in temperature sensor manufacturing, ensuring that products meet the highest standards of quality, safety, and environmental responsibility. Reputable manufacturers and established brand leaders, such as ourselves, recognize that maintaining these standards is integral to being world-class leaders. Conversely, inferior product manufacturers who may seek to cut costs at every opportunity may not value accreditations and certifications, compromising the reliability and safety of their products. Additionally, the focus on the “people” aspect through ISO 45001 ensures that our workforce operates in a safe and healthy environment, which is essential for maintaining high productivity and morale.

By prioritizing ISO certifications, we demonstrate our commitment to excellence and continuous improvement, benefiting customers across diverse industrial sectors.