Thermowells are critical for protecting temperature sensors from harsh process environments, ensuring accurate and reliable temperature measurements across various industrial applications. To maintain safety and performance, thermowell design must follow strict guidelines. ASME PTC 19.3 TW-2016 provides comprehensive standards for the mechanical design and performance of thermowells. This article explores the key aspects of ASME PTC 19.3 TW-2016, its importance in thermowell design, and practical applications in the industry.

Key Objectives and Scope of ASME PTC 19.3 TW-2016

ASME PTC 19.3 TW-2016 sets standards that ensure thermowells meet the structural integrity and performance needed to operate safely under various process conditions. The primary objectives include:

- Ensuring Safety: Providing design criteria that mitigate risks of mechanical failure, protecting both personnel and equipment.

- Enhancing Performance: Offering guidelines to optimize thermowell performance for accurate, reliable temperature readings.

- Standardizing Design: Establishing a consistent approach to thermowell design, promoting uniformity in installation and application.

The scope of ASME PTC 19.3 TW-2016 covers:

- Design Criteria: Including material selection, dimensional tolerances, and mechanical strength.

- Testing Procedures: Detailed methods for validating thermowell performance under expected conditions.

- Installation Guidelines: Best practices for installing thermowells to maintain their integrity and functionality.

For end users and project teams, adhering to ASME PTC 19.3 TW-2016 ensures that thermowells installed in high-stakes environments meet stringent industry requirements, supporting operational reliability and safety.

Importance of Adhering to ASME PTC 19.3 TW-2016

Adhering to ASME PTC 19.3 TW-2016 offers several benefits:

- Safety: The standard reduces risks of mechanical failures that could create dangerous conditions, helping protect personnel and equipment.

- Reliability: Thermowells designed according to ASME standards perform consistently under specified conditions, resulting in accurate, stable temperature measurements.

- Regulatory Compliance: Many industries require ASME standards to comply with safety and quality regulations.

- Building Trust: By following these standards, facilities can demonstrate a commitment to safety and quality, fostering trust with stakeholders and project teams.

Practical Applications and Industry Relevance

ASME PTC 19.3 TW-2016 applies across a range of industries where reliable temperature measurement is paramount. Practical applications include:

- Oil and Gas Industry: Thermowells must endure extreme pressures and temperatures. Adhering to ASME standards ensures that thermowells perform reliably under these demanding conditions.

- Chemical Processing: Chemical plants often involve corrosive environments and aggressive fluids. ASME guidelines for material selection and mechanical strength help ensure that thermowells withstand challenging conditions in such settings.

- Power Generation: In power plants, accurate temperature measurement is essential for both efficiency and safety. ASME PTC 19.3 TW-2016 provides criteria for designing thermowells that deliver reliable readings in high-stress environments.

Key Aspects of ASME PTC 19.3 TW-2016

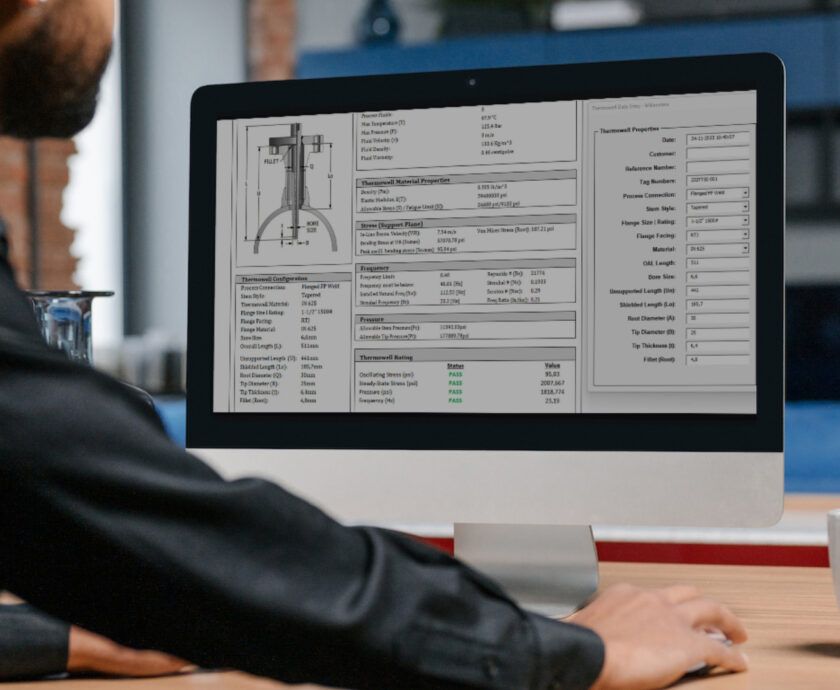

The standard includes several critical aspects that end users and project teams should consider:

- Material Selection: Guidelines for choosing materials that can withstand specific process conditions, including temperature, pressure, and chemical exposure.

- Dimensional Tolerances: Requirements for maintaining a precise fit and function of thermowells to ensure structural integrity and performance.

- Mechanical Strength: Criteria to ensure thermowells resist forces such as fluid flow-induced vibrations, which are common in high-flow applications.

- Testing and Validation: Procedures like pressure testing, vibration analysis, and fatigue testing to validate thermowell performance and safety.

Wrapping Up

With over 50 years of expertise, Thermo Electric Instrumentation has been designing and manufacturing thermowells that fully comply with all relevant standards, including ASME PTC 19.3 TW-2016, supporting end users and project teams in achieving reliable and safe operations.

ASME PTC 19.3 TW-2016 provides essential guidelines for the design, testing, and installation of thermowells, ensuring their safety and performance in industrial applications. By following this standard, we help end users and project teams install thermowells that meet the rigorous demands of various industries. Adhering to these guidelines enhances the accuracy and reliability of temperature measurement systems, contributing to safer and more efficient operations.