In settings such as furnaces, reactors, and glass kilns, maintaining accurate temperature readings in extreme heat can be a significant challenge. High temperatures, thermal shock, and the risk of material degradation all contribute to making reliable temperature measurement difficult. This article explores the common challenges faced in high-temperature environments and provides practical solutions for ensuring accuracy and reliability.

The Challenges of Extreme Heat

High-temperature environments present several challenges for temperature measurement:

- Thermal Shock: Rapid changes in temperature can cause thermal shock, which may lead to damage or failure of the sensor. Temperature sensors in these conditions need to be able to withstand such fluctuations without losing accuracy.

- Material Degradation: Prolonged exposure to extreme heat can degrade sensor materials, affecting their performance over time. The right selection of high-grade materials is critical to maintaining the accuracy and longevity of temperature sensors.

- Harsh Operating Conditions: Industrial processes often involve corrosive or abrasive substances in addition to high heat. This combination can accelerate sensor wear and tear, making it difficult to obtain reliable temperature readings.

Features That Make Sensors Suitable for High-Heat Applications

Temperature sensors designed for extreme environments must incorporate specific features to overcome these challenges:

- Durable Construction: Sensors made from high-grade materials, such as Inconel and stainless steel, can withstand extreme heat and resist corrosion, ensuring durability and consistent performance over time.

- Wide Temperature Range: Sensors capable of measuring temperatures up to 2,700°C are suitable for applications such as high-temperature furnaces, reactors, and refining processes.

- Thermal Shock Resistance: Sensors designed to handle rapid temperature changes without compromising performance are essential for environments with fluctuating heat levels.

- Precise Calibration: Calibration is critical for maintaining sensor accuracy, particularly in extreme environments. Sensors calibrated in accredited laboratories, such as our in-house calibration lab, are more likely to provide consistent, reliable readings under harsh conditions.

The Importance of Calibration in High-Temperature Environments

Calibration plays a key role in ensuring that high-temperature sensors provide accurate readings in extreme heat. Without regular calibration, sensors may drift over time, leading to inaccurate measurements that can compromise both safety and product quality.

An accredited calibration laboratory, such as one that follows ISO 17025 standards, ensures traceability and accuracy of measurement results. Traceable calibration means that the sensor’s readings are tied back to international standards, providing confidence in the data’s reliability.

Regular calibration is especially important for sensors exposed to thermal cycling, which can cause measurement drift. A consistent calibration schedule helps to detect and correct these issues, ensuring that the sensor continues to operate within acceptable tolerances.

Practical Solutions for Reliable Temperature Measurement

To achieve accurate temperature measurement in extreme environments, several key practices should be followed:

- Material Selection: Choose sensors made from materials that can withstand both the temperature and the chemical properties of the environment. For example, Inconel and stainless steel are often chosen for their ability to handle high temperatures and resist corrosion.

- Customized Solutions: Customizing sensors to fit the specific needs of an industrial setup can improve accuracy and reliability. Custom sheath materials, mounting configurations, and calibration points help tailor the sensor to the environment, reducing the impact of external factors.

- Routine Calibration: Establish a regular calibration schedule to maintain accuracy over time. Calibration performed by accredited laboratories ensures that the sensors provide traceable and reliable data, even in extreme environments.

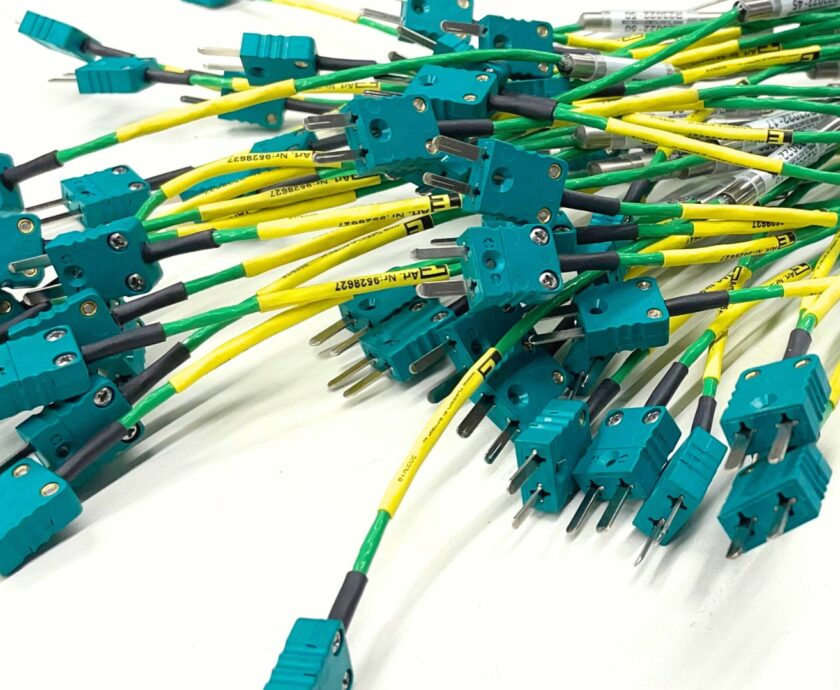

At Thermo Electric Instrumentation, we understand fully that measuring temperature in extreme heat environments requires specialized sensors and careful planning to address the challenges of thermal shock, material degradation, and harsh operating conditions. This is why we help our customers select sensors with durable construction, wide temperature ranges, and precise calibration. By implementing best practices for routine calibration and material selection, industries can ensure accurate and reliable temperature readings.

So remember, achieving consistent temperature measurements in high-temperature environments is critical for maintaining safety, product quality, and operational efficiency. With the right temperature sensor partner, the challenges of extreme heat can be overcome, leading to better performance and reliability in industrial processes.